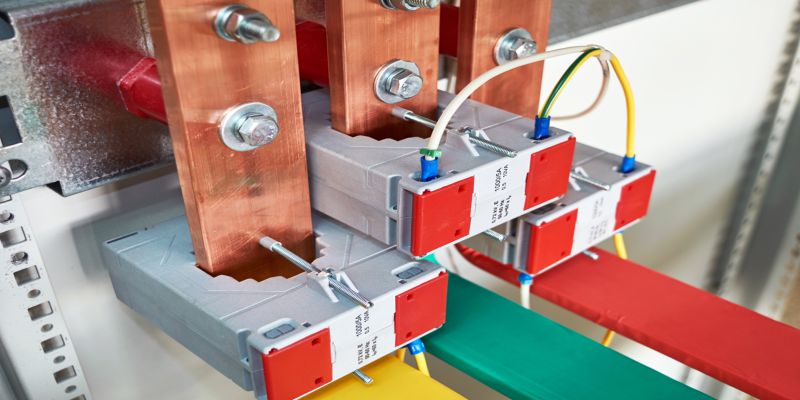

Busbar

Busbar manufacturing requires unique capabilities and experience. Our full understanding and expertise in dealing with red metals and aluminum materials plus our existing partnerships with approved secondary suppliers allows us to provide you with a more finished product that meets your exact requirements.

As demand for electric vehicles has exploded in recent years, we have been adding new technical capabilities to produce custom busbars to transmit power in all types of electric vehicles, whether hybrid, all-electric, or autonomous (self-driving).

Custom metal stamped busbars of different sizes and complexities are required to transmit current from high-powered battery packs to a variety of electrical applications including:

PV INTERCONNECT BUSBAR

| Busbar |

| Width |

3.0 mm to 8.00 mm |

| Thickness |

0.1 MM TO 0.5 MM |

| Standard coating |

15µm TO 25 µm ( per side) |

| LEADED COATING |

60 SN/40PB

62SN/36PB/2Ag |

| LEADED FREE COATING |

100 Sn

Sn96.5/Ag 3.5

Sn95.5/Ag4.0/Cu0.5 |

| Camber |

≤ 3 mm / 1000 mm |

| Softness |

|

Tensile strength |

Yield strength |

Elongation |

| Flexiable |

150 N/MM2 To 200 N/MM2 |

≤ 70 |

≥ 25 % |

| Super Flexiable |

≤ 60 |

≥ 30 % |

| Extrem Flexiable |

≤ 55 |

≥ 35 % |

| TOLERANCE |

|---|

| Testing Name |

Busbar |

| Width |

± 0.2 mm |

| Thickness |

± 0.05 mm |

| Coating Thickness |

≤1.707 X 10 Ωmm @ 20 C |

| Coating type |

Thickness of coating can vary from 0.010 mm to 0.050 mm |

| Specifications of the solder coating |

|---|

| Busbar |

| Tin Coat Thickness |

≥20µm(** other thickness is Available on request) |

| Tin Coat thickness error |

±0.009 mm |

| Type of Coating& Composition |

Liquefaction Temperture(*C) |

| Leaded (Non RoHs)-60sn40pb |

190˚C |

| Leaded (Non RoHS)-62Sn36pb2Ag |

189˚C |

| RoHS Complianced Lead Free-96.55n3.5Ag/Sn100/SnAgCu |

221˚C |

APPLICATIONS

- Sunroofs

- Sensors

- Communications

- Windows

- Remote Controls

Finishing Services

- Hardware Insertion

- Complex Busbar Bending

- Epoxy Coating

- Specialty Coating for Insulators

- Metal Plating

- Plastic Injection Molding

- Plastic Overmolding

- Welding

- Deburring/Cleaning

BUSBAR TYPES

- Personal Computers and Electronics

- Renewable Energy and Line Energy

- Surge Protection Devices

- Electrical Panels

- Single or Multi-Conductor Batteries

BUSBAR MATERIALS

We provide comprehensive services to take busbar designs from concept to completion.

- Prototyping

- Design Assistance (material selection, dimensions, tolerance, optimal performance at lowest cost)

- Tool Design & Build

- Automated Assembly

We are committed to mistake-proof processes. You can rely on us, as we have one of the industry's largest and most experienced engineering, design, and tool & die teams with more than 60 industry experts and craftsmen.