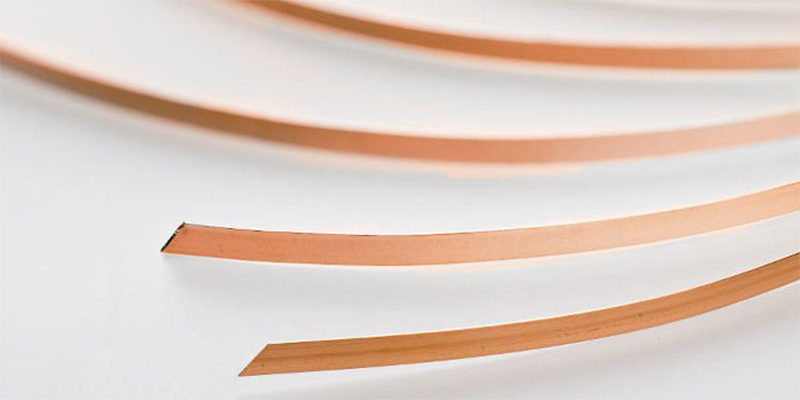

Flat Wire

Best wire products manufactured via class-leading rolling operations to meet the finest tolerances. Our experienced engineers draw and flatten round wire to achieve consistent flat cross-sections in custom thicknesses and widths. Using pioneering process monitoring technologies, we can also prescribe intermediary annealing stages to remove internal stresses and yield the toughest possible wire products based on a broad range of alloys, from stainless steels to nitinol flat wire.

- TITANIUM ALLOYS

- NITINOL ALLOYS

- NICKEL ALLOYS

- COBALT ALLOYS

- TUNGSTEN

- COPPER CLAD ALUMINUM

- PHOS/BRONZE

- STAINLESS CLAD COPPER

- TIN PLATED COPPER

- BACKING STRIP

- CABLE WRAP

- GLASS BUSBAR

- PISTON RING

- WIPER BLADE

- BLENDER BLADE

- CONDUCTORS

- HELICAL WRAP WIRE

- SEALS

- MEDICAL BRAID WIRE

- FASTENERS

- RF CABLE WIRE

- SHIELDING

Precision-rolled flat wires in an unparalleled range of alloys and grades. With a comprehensive list of rolling, annealing, edging, and finishing capabilities, Best wire Specialty Wire Products can deliver stainless steel flat wire profiles across the full spectrum of stainless classifications (austenitic, ferritic, martensitic, etc.). We also offer an exhaustive list of specialist alloys: Shape-memory nitinol flat wire; cobalt-based superalloys; high-strength tungsten profiles; and much more.

Best Wire Specialty Wire Products flat wire products are made available in a choice of formats to suit the broadest possible range of market requirements. Our precision flats are manufactured with absolute control over edge profile, width, thickness, and other key parameters to ensure optimal delivery and application in an array of end-use environments. Whether your wire application requires a round edge or square edge, or something else entirely, Best Wire's wire manufacturing capabilities are able to meet your precision wire needs.

Proper Spool Handling

To prevent tangled or shifted wrap, always handle/store all received, sampled, and partially used spools in “eye to the side” direction.

Stainless Steel

Known for its versatility, stainless steel is used in a wide array of common items including appliances, medical instruments, and cars. We offer eight controlled atmosphere annealing lines as well as stainless coil cleaning, Ungerer tension leveling, slitting, edging, and oscillate winding.

Nickel

Used primarily for parts requiring excellent corrosion and strong magnetic properties such as lead wires, battery components, transducers, sparking electrodes, and heat exchangers. Our engineers will work closely with you in material selection and tailoring your nickel strip needs to your specific application.

Cobalt

Our cobalt strip coil products are typically used for products such as jet engines, turbines, and dental implants. Our engineers, product managers, and mill operators have deep knowledge and experience in rolling these critical thermally stable alloys primarily for, but not limited to, aerospace, and turbine applications.

Titanium

Commercially pure titanium is generally used for orthopedic implants, while the alloys are commonly produced with the addition of vanadium or aluminum for applications such as aerospace or sports equipment. We will assist you from R & D to large production runs, over the lifetime of your product.

Nitinol

Nitinol is used for applications that require the material to remember its original shape, making it a natural for medical components and eyeglass frames. Our team of product managers and highly skilled engineers are experienced in producing this unique alloy for demanding end uses.

Special Metals

Best Wire offers many production and material capabilities that are manufactured to our customers specifications, right down to the packaging and delivery. We strive to partner with our clients to create the best metal solutions to their specific business needs, which is why we have established ourselves as industry leaders.

Our Approach

With a customer-centric approach to new and established product development, we always look to share our extensive resources to the benefit of our clients. Best Wire Specialty Wire Products’ world-class development innovation team routinely delivers bespoke flat wire solutions to customers all over the world, from custom compositions to unique dimensional requirements.

Flat Wire

Thickness Range

0.0002” – 0.210”(0.00508 mm – 5.33 mm)

Width Range

0.002” – 1.00”(0.05 mm – 25.40 mm)